The innovation of CNC machining in industrial processes is characterised by three superlatives: accuracy, efficiency, and adaptability. Melbourne, Australia, has a huge need for CNC machining services, and more and more businesses from a variety of sectors and uses are using these services. We’ll introduce you to the world of CNC machine tools in Melbourne in this thorough guide, covering everything from their uses and capabilities to the services that may be tailored to your needs. By making custom components with specialised T bolts and utilising the latest high technology, the CNC machining Melbourne industry has been at the cutting edge.

Understanding CNC Machining

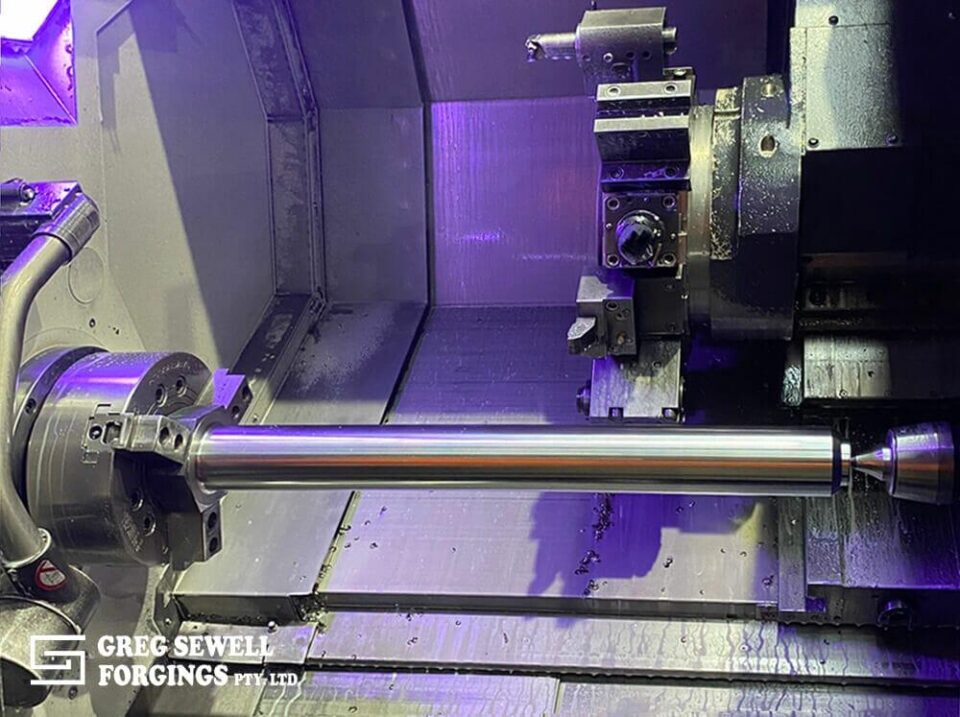

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer control to help shape and complete raw materials into finished parts with the benefit of accurate dimensions. With a computer’s instructions, CNC machines can produce intricate components down to the micron level and can give their precise location. This technology is now core to many industries, from aerospace to automotive, medical, and assorted engineering applications.

Importance of CNC Machining

CNC machining is an indispensable tool in modern manufacturing and engineering because it delivers precision and fast, reliable production of economic parts. With CNC machines, exact and consistent components can be manufactured, and tightly fitting tolerances and exacting specifications are just part and parcel. This automation cuts down on manual labour and errors while simultaneously raising efficiency so that lead times are shortened and production costs fall further. By its very nature, CNC machines are capable of constant renewal to keep up with the changing shapes of the industry. Manufacturers can quickly respond as new customer needs pop up, market trends alter, or even technological developments occur.

Its adaptability means various components, ranging from simple shapes to highly complex geometries, can be produced using different materials such as metals, plastics, and composites. In addition, CNC machining in Melbourne drives innovation in product design and engineering by making the production of intricate and complex pieces possible. Overall, CNC machining plays a vital role in ensuring quality and continuity of production across many different industries throughout the economy.

CNC Machining Services in Melbourne

Melbourne boasts a thriving CNC machining sector, with numerous companies offering a wide range of services, thus catering to both large and small enterprises. These services include:

- Precision Machining: CNC machining in Melbourne facilities are particularly skilled at precision machining, producing components with complex geometries and fine surface finishes. Whether milling, turning, or grinding, the expertise and equipment in such facilities can cope with complex projects very precisely.

- Custom Fabrication: Melbourne’s CNC machining services also handle custom fabrication applications, from prototyping to production runs. Whether clients need one-off prototypes or large volumes of production, CNC machining facilities can accommodate any request.

- Material Expertise: Melbourne’s CNC machining industry has rich experience with many materials, including metals (e.g., copper, aluminium, titanium), plastics, and composites. Whether the material is aluminium, stainless steel, or an engineering plastic, CNC machining services are capable of various materials.

T Bolts: Enhancing CNC Machining Applications

T bolts are specialised fasteners commonly used in CNC machining applications to secure workpieces to machine beds or fixtures. They feature a unique T-shaped head that provides stability and prevents movement during machining operations. CNC machining Melbourne facilities often utilise stainless steel t bolts to ensure precise and repeatable machining processes, enhancing efficiency and accuracy.

Benefits of CNC Machining

The adoption of CNC machining Melbourne offers numerous benefits for manufacturers and clients alike, including:

- Precision and Accuracy: CNC machining produces high-precision results from materials that apply consistent tooling to meet design tolerances.

- Efficiency and Productivity: Automation makes manufacturing faster, more profitable, and less risky.

- Cost-Effectiveness: Despite the initial setup costs, CNC machining has lower long-term operating costs in terms of scrap, rework, and labour savings.

- Versatility and Flexibility: CNC machining can make a wide variety of parts without major changes to setup from simple geometries.

Materials Used in CNC Machining

CNC machining Melbourne uses a wide variety of materials with different properties and suitability for various types of applications. Copy metals such as aluminium, steel, stainless steel, and brass offer strength, durability, and machining properties, making them ideal for industries such as aerospace or the automotive industry. Glass plastics such as acrylics, polyethylene, and ABS are easy to machine. They also provide advanced chemical resistance. For this reason, many are used in consumer goods or signage.

Composites like carbon fibre or glass fibre have low weight, high strength, and good corrosion resistance. Therefore, these materials are common in aerospace, automotive, and recreational products. The aesthetic appeal of wood, along with its machinability and ability to be worked, has been the push-button for furniture, construction, and handicrafts. Additionally, ceramics and foam have unique applications in high-temperature environments, electronics, and insulation. With CNC machining in Australia capable of working with a wide range of materials, manufacturers can select the most appropriate material for their needs. This is how they ensure optimal performance and quality for their finished products.

Conclusion

CNC machining Melbourne has become essential in manufacturing, providing precision, efficiency, and versatility across various applications. From prototyping to using innovative T bolts, the CNC machining industry continues to take charge of advancing technology and quality. As demand for high-quality, tailor-made components rises in Australia and abroad, Melbourne’s CNC machining industry is poised to satisfy clients’ ever-changing requirements in diverse fields.